- New

- Sale

- Temperature

- Humidity

- Pressure

- Light Intensity & Motion

- Air Quality

- Flow

- Modbus | Wireless Modbus

- Room controller

- EtherCAT P

- Accessory

Passive temperature transmitters

Passive temperature sensors are an important component of various industrial and private control and temperature measurement technology applications.

Our THERMASGARD® passive temperature sensors are used to control the indoor climate, as outdoor temperature sensors or for temperature detection on cables, pipes or heating systems.Everything about temperature sensors

Contents

What is a temperature sensor?

A temperature sensor is an electronic component that measures the temperature and transmits it as an electrical signal to the display, the control unit or the heating system. They do not require an external energy source, they are simply supplied with voltage. The downstream control system measures the resistance of the temperature sensors, which changes according to the ambient temperature. The temperature/resistance ratio can be read off exactly in a comparison table (resistance values).

There are different types of temperature sensors depending on the measuring task and area of application. S+S offers a wide range of passive temperature sensors for measurement technology - from surface-mounted or flush-mounted temperature sensors and passive outdoor temperature sensors to passive cable, room pendulum, duct temperature or passive immersion temperature sensors.

Functionality of temperature sensors

Resistance-based temperature sensors

PTC thermistors (PTC: Positive Temperature Coefficient):

These sensors, such as Pt100 or Pt1000, increase their resistance as the temperature rises and offer high accuracy and stability. A major advantage of these sensors is that the characteristic curve is linear and they are uniformly standardized. For example, the resistance of a PT1000 sensor at 0°C is always 1000 Ohm.

At S+S Regeltechnik we offer you the following PTCs (thermistors) depending on the temperature sensor:

- Pt100 sensors: Pt100 class A, Pt100 class B, Pt100 1/3 class B, Pt100 1/10 class B

- Pt1000 sensors: Pt1000 class A, PT1000 1/3 DIN class A, PT1000 1/10 DIN class A, Pt1000 class B

- Ni sensors: Ni1000 1/2 DIN class B, NI1000 class B

- NI1000TK5000 sensors

- LM235Z

- KTY sensors: KTY81-210, KTY81-110, KTY11-6

As we attach great importance to customer satisfaction, we can of course also install sensors that are not listed. Simply send us an inquiry

Thermistors (NTC: Negative Temperature Coefficient):

NTC thermistors reduce their resistance as the temperature rises and are made of metal oxides or semiconductors.

S+S Regeltechnik has the following NTCs (thermistors) in its range:

- NTC1.8K

- NTC2.2K

- NTC10K

- NTC10K Precon

- NTC10K Carell characteristic

- NTC20K

As we attach great importance to customer satisfaction, we can of course also install sensors that are not listed. Simply send us an inquiry

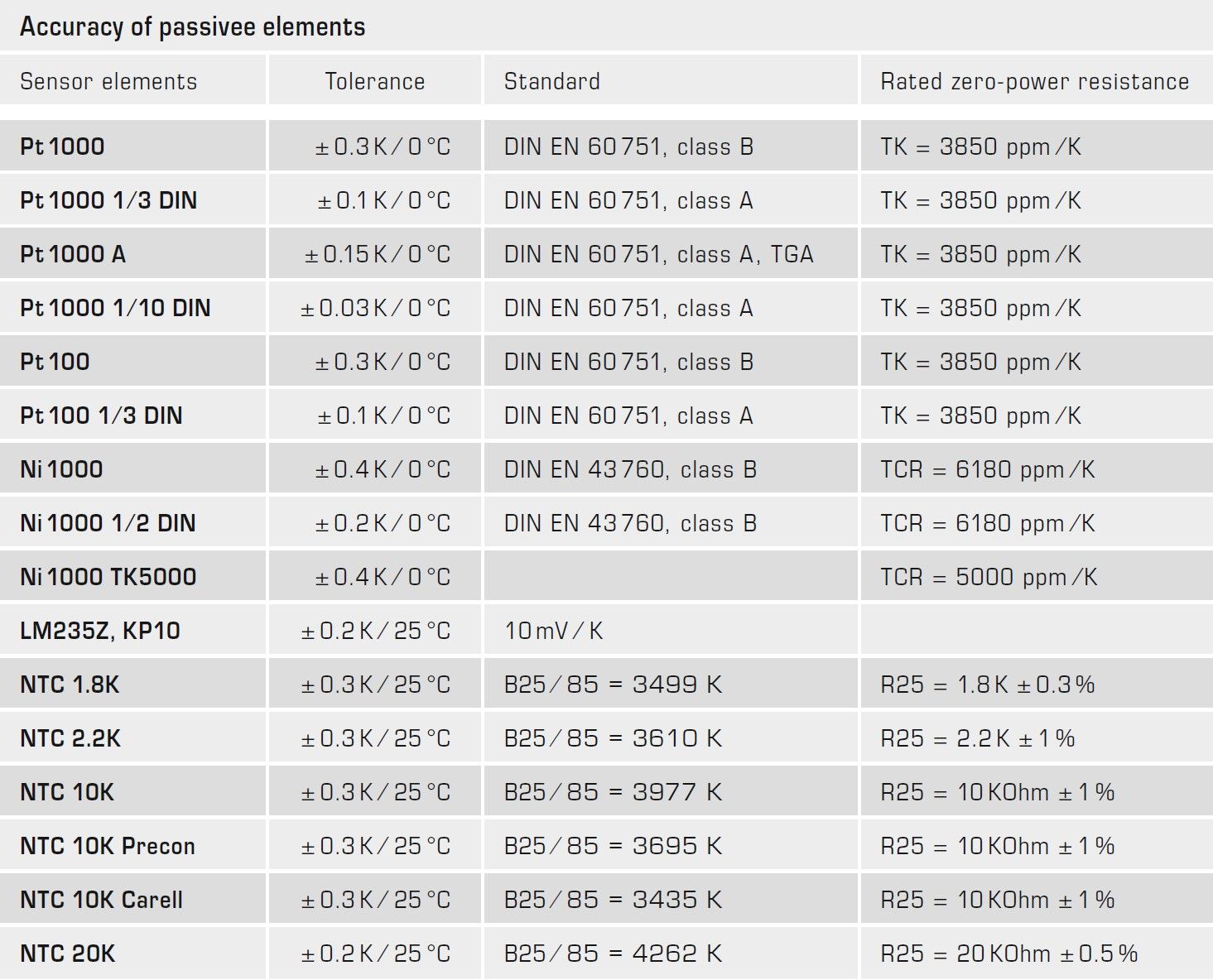

Basically, the higher/better the class, the more accurate the sensor. This accuracy is categorized in the DIN classes. The picture shows the different tolerances of the various sensor types. S+S offers this for download in the download area under "Useful information". In the PDF you will also find the resistance table for each sensor

Thermocouples

Thermocouples consist of two different metals that generate a low electrical voltage when there is a temperature difference. They are ideal for use at high temperatures and offer a fast response.

Selection criteria for temperature sensors

1. design of the temperature sensor

The design of the sensor depends on the type of measurement and the area of application:

- Insertion probe: For core temperature measurements in liquids or solids.

- Screw-in sensor: For measuring in liquid or gaseous media, e.g. in heating technology.

- Cable sensor: Flexible use for a wide range of applications.

- Surface sensor: For measuring the temperature of surfaces.

- Pipe contact sensor: For indirect measurement of the temperature of pipes.

S+S Regeltechnik offers you 4 of 5 of these types of sensors: Screw-in sensors, cable sensors, surface sensors and pipe contact sensors.

2. sensor type

Different sensor types can be used depending on the requirements:

- Pt100/Pt1000: Precise measurement, ideal for industrial applications.

- NTC: More cost-effective and faster response, suitable for household appliances, among others.

- Thermocouples: For high temperatures and fast response times.

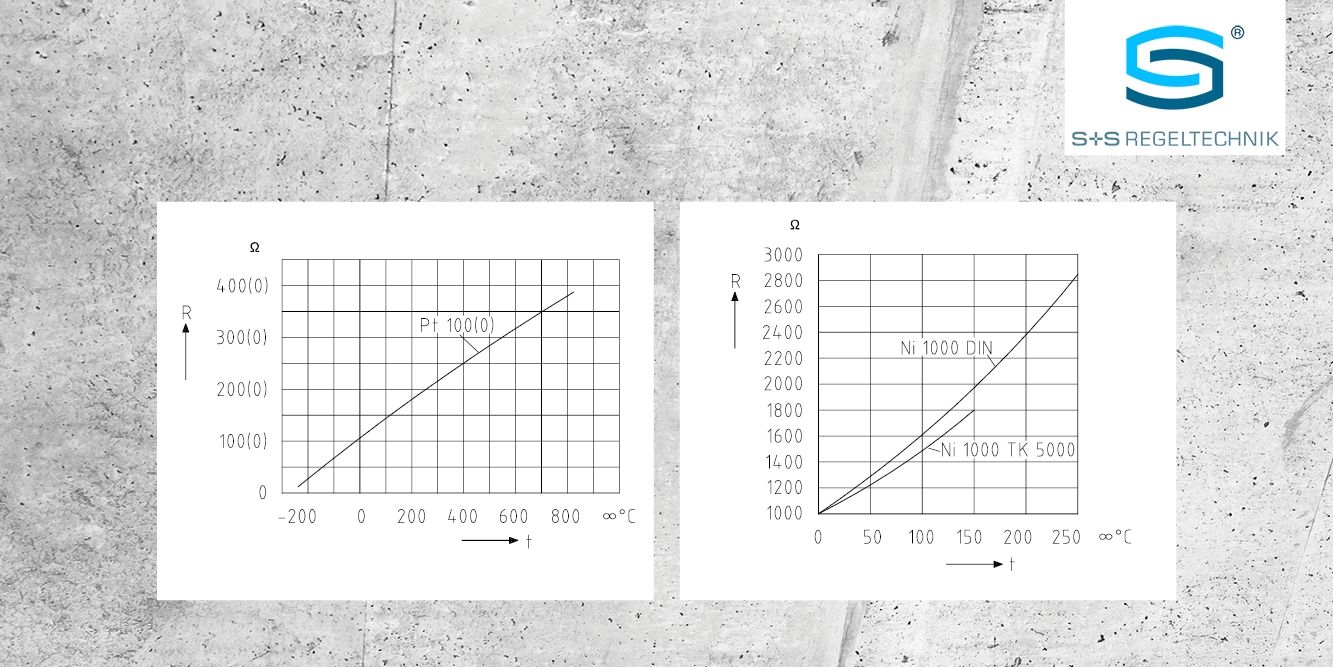

The figure shows characteristic curves of several sensors for illustration purposes. In this case, the graph on the left shows the characteristic curve of a PT100 and PT1000 sensor. The graph on the right shows the NI1000 and NI1000 TK5000 sensors.

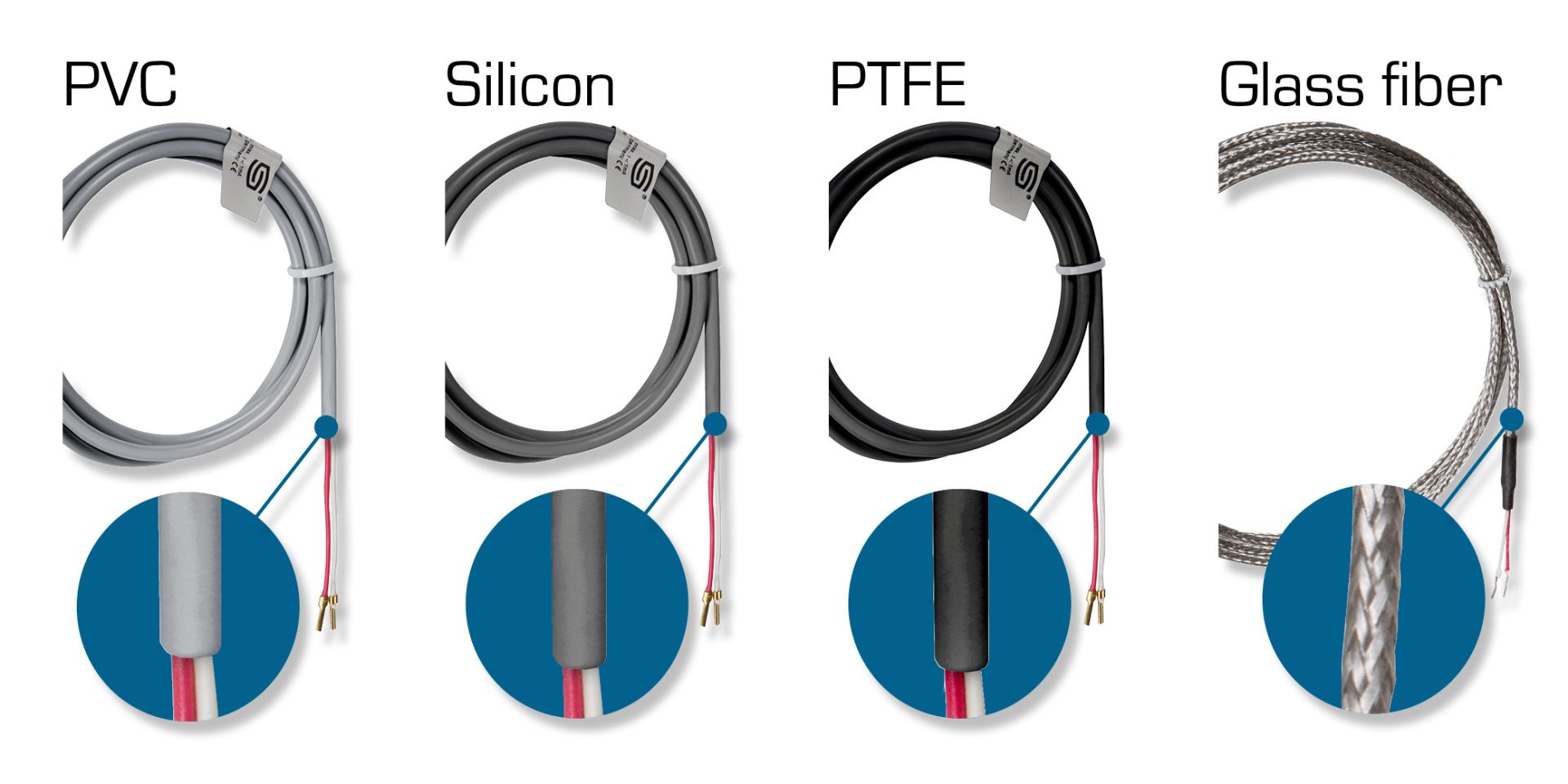

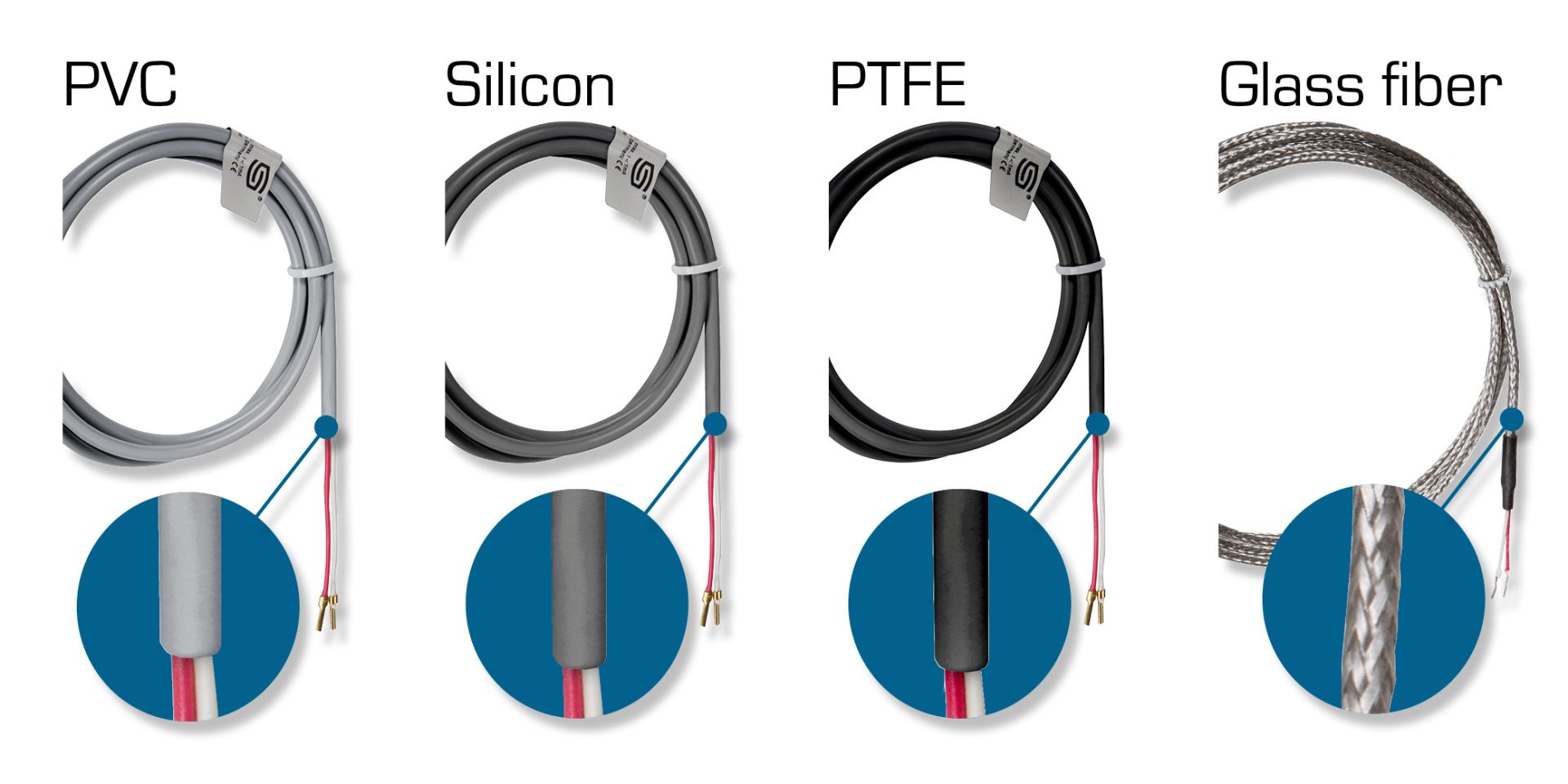

3. sensor cable (cable temperature sensor)

Here too, there are different cable types that are used depending on the requirements. These differ mainly in terms of the cable material and the corresponding minimum/maximum temperature:

- PVC, LiYY 2x0.25mm²: -35...+105°C/ -31...+221°F

- Silicone, SiHF 2x0.25mm²: -50...+180°C/ -58...+356°F

- PTFE, 2x1.0mm²: -50...+250°C/ -58...+482°F

- Glass silk, 2x0.25mm²: -50...+350°C/ -58...+662°F

4. measuring medium and temperature range

Take into account the medium in which the measurement is to take place (air, liquid, gas) and the required temperature range:

- Air: Room and outdoor temperature sensor.

- Liquid: screw-in and immersion sensors.

- High temperatures: Thermocouples.

5. mechanical connection

Make sure that the sensor can be mechanically integrated correctly into the process. Select the appropriate thread size, sleeve length and sleeve diameter.

6. environmental conditions (IP protection class)

Take into account the ambient conditions such as pressure, humidity, dust and chemical influences. Select suitable materials and protection classes (e.g. IP protection classes).

How do I find the right temperature sensor?

To meet all these specifications, S+S offers filters on the article overview to make it easy for customers to find the right temperature sensor. Simply filter your required attributes and you will receive the appropriate product.

Frequently asked questions about temperature sensors (FAQ)

How do I check the function of a temperature sensor?

You can use a multimeter to measure the resistance of a resistance-based sensor and compare it with the technical data. You will need a special multimeter for thermocouples.

Which extension cable can be used for temperature sensors?

The choice of extension cable depends on the ambient temperature and the specific requirements. Suitable cable types include PFA, PVC, silicone and glass fiber. You can also buy all cable temperature sensors with these different cable types from S+S.

How do I connect the temperature sensor correctly?

Refer to the wiring diagrams in the operating instructions for your temperature sensor to ensure correct wiring.

The main connection types are 2-wire, 3-wire and 4-wire. You must connect the respective number of conductors to the building management system (BMS) accordingly.

How can I protect a temperature sensor from certain influences?

Select a sensor that is designed for your specific measuring task and, if necessary, use additional accessories such as immersion sleeves, sun protection or other accessories suitable for the application.

What applications do passive temperature sensors have?

Passive temperature sensors are versatile and are used in a variety of industries and applications to ensure accurate temperature measurements. Some of the following examples represent the main industries in which our customers use our sensors. By no means does this include all applications and areas of use for temperature sensors.

- Heating, ventilation and air conditioning technology (HVAC)

Passive temperature sensors are used in heating, ventilation and air conditioning technology to monitor and control room and outdoor temperatures. They are essential for controlling boilers, air conditioning systems, heat pumps and ventilation systems to ensure energy efficiency and comfort. - Building automation

In building automation, temperature sensors ensure precise control of heating, ventilation and air conditioning (HVAC) systems. They help to optimize the indoor climate, reduce energy consumption and increase comfort. - Industrial plants

Passive temperature sensors are widely used in industrial plants to monitor and control processes. They measure temperatures in machines, production lines, reactors and storage tanks to maximize efficiency and ensure product quality. - Food and beverage industry

In the food and beverage industry, temperature sensors are used to monitor and control temperatures during production, storage and transportation. This is crucial to ensure compliance with hygiene standards and product quality. - Pharmaceutical industry

In the pharmaceutical industry, precise temperature measurements are essential for the production and storage of medicines. Temperature sensors are used in production plants, laboratories and storage facilities to ensure the integrity and efficacy of products.

What is the difference between active and passive temperature sensors?

Active temperature sensor:

- Supplied by external energy source

- Agile communication with the downstream control system

- Active reaction to changes in your environment

- Can be combined with other parameters such as humidity, pressure, air quality, etc

- Active intervention in temperature control possible - thanks to smart room operating units

Passive temperature sensor:

- No external power supply required, encapsulated element

- The electrical resistance in the temperature sensors is measured by applying a voltage

- Changes in resistance indicate changes in the ambient temperature (easy to read in the temperature-resistance table)

- Most favorable variant if no other parameters are to be read out

When is a temperature transducer required?

Transmitters are required if temperatures are to be recorded from remote measuring points in order to compensate for cable lengths using standard signals (0-10V, 4-20mA, bus technologies such as Modbus or W-Modbus) and to generate standard signals.

Order temperature sensors online at SplusS.de - quick and easy

In our online store you will find temperature sensors for almost every application. The convenient navigation makes it easy for you to find the device you are looking for.

Do you have any questions about the product? Our service team is always available by phone or email to help you navigate and purchase online. Find the right humidity sensor for your application today!

Quality products - Made in Germany!

Your requirements are our motivation: We develop and manufacture our humidity sensors directly at S+S in Nuremberg and guarantee the highest quality for trouble-free operation and a long product service life. Our stock items are usually dispatched by DHL within 1-2 working days.